Current Research Topics

Miniaturised human blood preparation for next-generation sensing

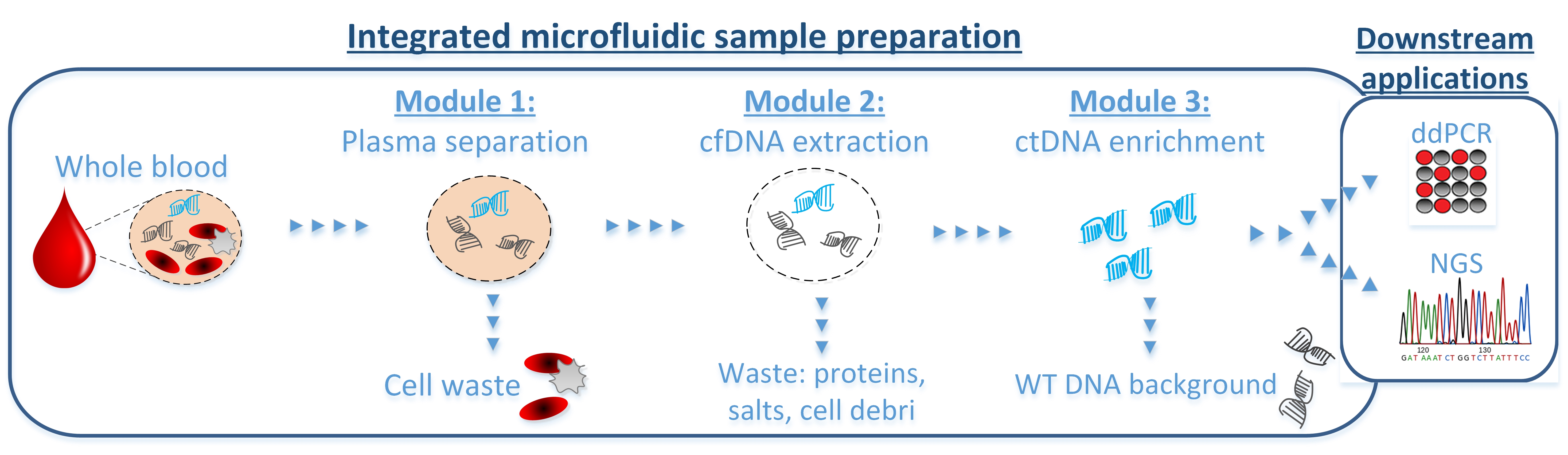

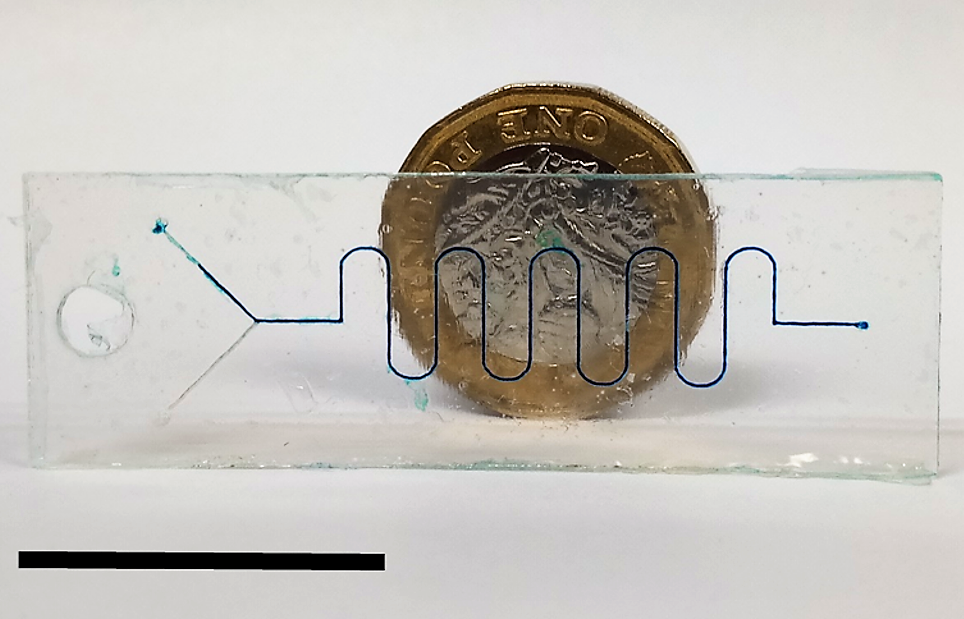

The analysis of cell-free nucleic acids (cfNAs) from simple blood draw (so-called “liquid biopsies”) is appealing from a diagnostic, prognostic and theranostic point-of-view. It can reveal a range of pathologies from cancer, fetal chromosomal abnormalities, and transplant rejection, without the need for invasive sampling of tissues and can be easily repeated. However, the difficulty in controlling the pre-analytical phase to obtain robust and reliable results, has emerged as the bottleneck in the race to the cost-effective clinical implementation of these biomarkers, along the present cost and turn-around time to obtain results. We are developing novel devices for the preparation of blood samples, with an emphasis on pre-analytical workflows for the analysis of circulating DNA. A lot of our early work has focused on the design, manufacturing and characterisation of miniaturised hydrodynamic plasma separation. We have demonstrated the use of microfluidic networks comprising constrictions and bifurcations to separate whole blood at the microscale. We are using a range of methods to validate our blood plasma separation microfeatures, over the years this has included: automated cell counting, flow cytometry, quantitative and non-quantitative PCR and spectrophotometry. Our most recent work focuses on the extraction of circulating nucleic acids from plasma and enrichment of circulating tumour DNA.

Relevant Publications

- Mielczarek, W. S., Obaje, E. A., Bachmann, T. T. & Kersaudy-Kerhoas, M. Microfluidic blood plasma separation for medical diagnostics: is it worth it? 21 Sep 2016 In : Lab on a Chip. 16, 18, p. 3441-3448 8 p (Journal)

- Liga, A. D.B Vliengenthart, W. Oosthuyzen, J. Dear and M. Kersaudy-Kerhoas (2015). Exosome isolation: A microfluidic road-map . Lab On A Chip, DOI:10.1039/C5LC00240K (Journal)

- M Kersaudy-Kerhoas, MPY Desmulliez, J Norman (2014). Direct Fetal DNA Fraction Enrichment Using Microfluidic Sample Preparation of Maternal Blood for Non-Invasive Prenatal Testing. Arch Dis Child Fetal Neonatal Ed 2014;99:A2 (Journal)

- M.Kersaudy-Kerhoas and E.Sollier (2013). Micro-scale blood plasma separation: from acoustophoresis to egg-beaters. Lab Chip;13(17):3323-46 (Journal)

- Maïwenn Kersaudy-Kerhoas, Resham Dhariwal, Lionel Jouvet, Marc P. Y. Desmulliez (2010). Hydrodynamic blood plasma separation in microfluidic channels. Microfluidics and Nanofluidics Vol 8(1), pp 105-114 (Journal)

- Kersaudy-Kerhoas M, Kavanagh DM, Dhariwal RS, Campbell CJ, Desmulliez MP. (2010). Validation of a blood plasma separation system by biomarker detection. Lab Chip, 2010,10, 1587-1595 (Journal)

Relevant Funding

Fast prototyping of microfluidic devices

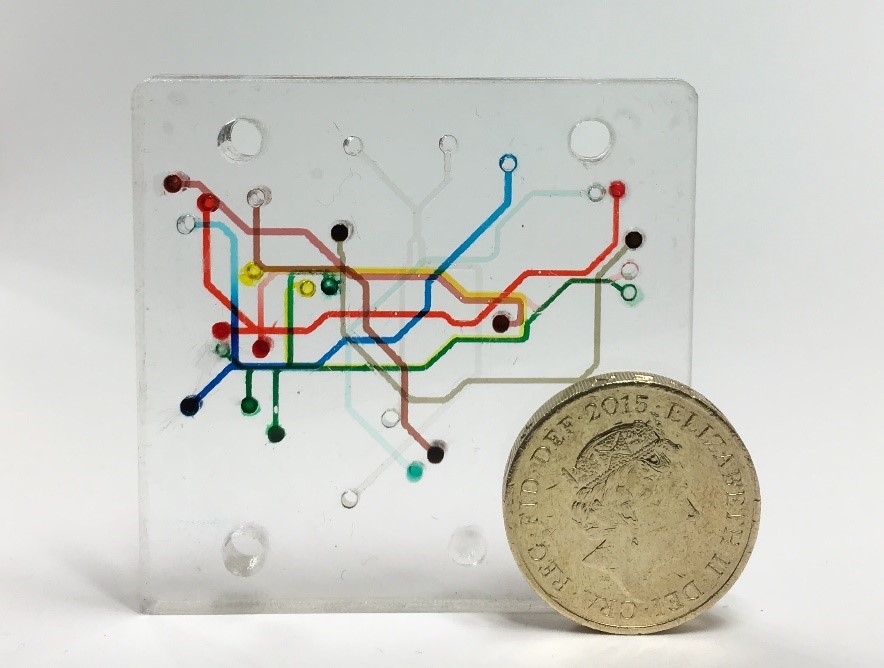

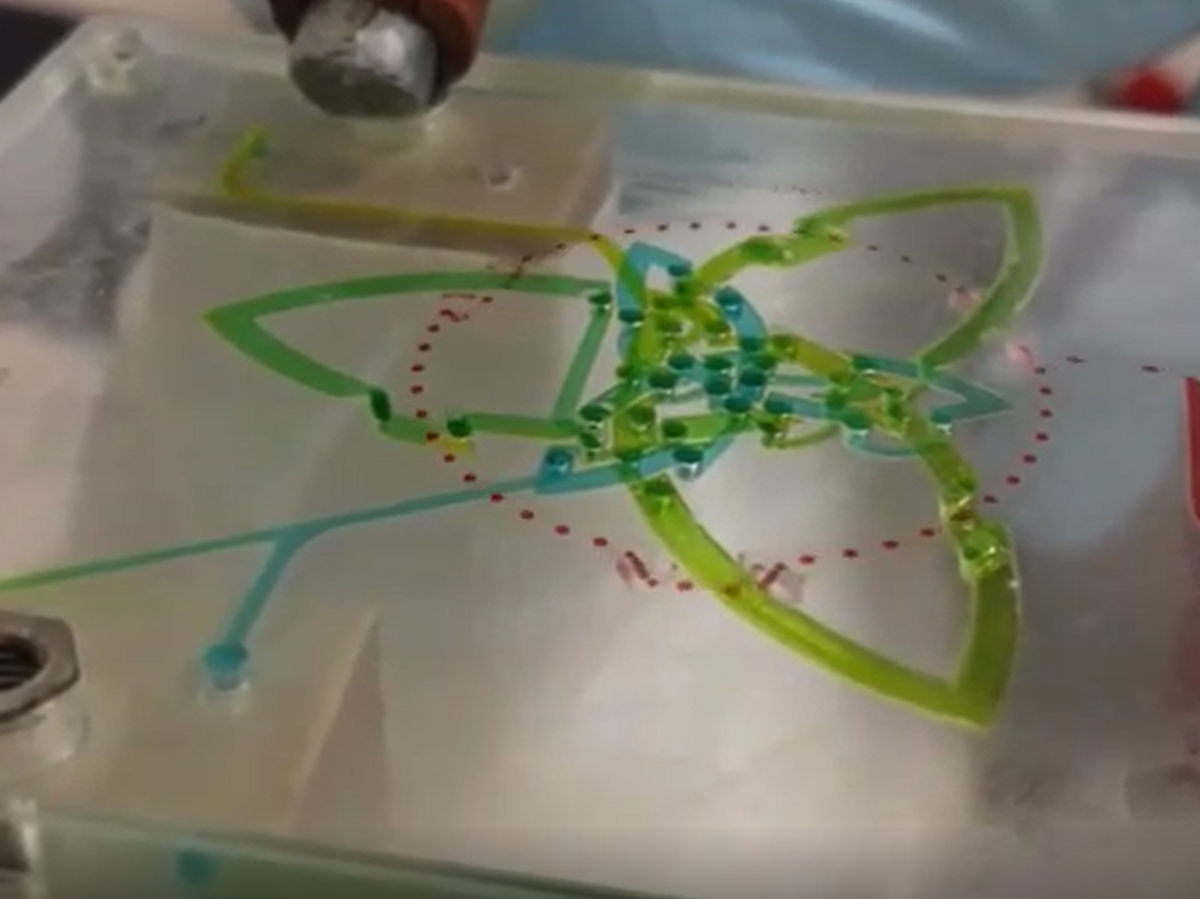

The rapid translation of research from bench to bedside, as well as the generation of commercial impact, has never been more important for both academic and industrial researchers. It is therefore unsurprising that more and more microfluidic groups are investigating research using a wide range of thermoplastics which can be readily translated to large-scale manufacturing, if the technology is taken to commercialisation. While structuring, via additive or subtractive manufacturing, is becoming relatively easy through the use of commercial grade devices, reliable and fast assembly remains a challenge. In this article we propose an innocuous and cost-effective, under-two minute technique which enables the bonding of multiple Poly(methyl-methacrylate) (PMMA) layers. This bonding technique relies on the application of small amounts (10 µl/cm2) of ethanol, low temperatures (70°C) and relatively low pressures (~1.6 MPa). Our characterisation analysis shows that using a bonding time of 2 minutes is enough to produce a strong bond able to withstand pressures always above 6.2 MPa (with mean of 8MPa, highest reported in literature), with minimal channel deformation (<5%). This technique, which we demonstrate on assembly comprising up to 19 layers, presents an exciting improvement in the field of rapid prototyping of microfluidic devices, enabling extremely fast design cycles in microfluidic research with a material compatible with mass-manufacturing, thus allowing a smoother transition from the lab to the market. Beyond the research community, this robust prototyping technique has the potential to impact on the deliverability of other scientific endeavours including educational projects and will directly fuel the fluidic maker movement.

Relevant Publications

- Liga, A., Morton, J. A. S. & Kersaudy-Kerhoas, M. Safe and cost-effective rapid-prototyping of multilayer PMMA microfluidic devices. Dec 2016 In : Microfluidics and Nanofluidics. 20, 12, 164 (Journal)

- Ongaro, A. E., Conoscenti, G., Liga, A., Brucato, V., Desmulliez, M. P. Y., Howarth, N., La Carrubba, V. & Kersaudy-Kerhoas, M. Ultra-fast-prototyping of PMMA structures for micro-engineering applications: Choosing the right material. 2017 Advances in Manufacturing Technology XXXI – Proceedings of the 15th International Conference on Manufacturing Research, ICMR 2017: Incorporating the 32nd National Conference on Manufacturing Research. Gao, J., El Souri, M. & Keates, S. (eds.). IOS Press, Vol. 6, p. 181-186 6 p. (Advances in Transdisciplinary Engineering) (Journal)

- Bridle, H., Morton, J. A. S., Cameron, P., Desmulliez, M. P. Y. & Kersaudy-Kerhoas, M. Design of problem-based learning activities in the field of microfluidics for 12- to 13-year-old participants—Small Plumbing!: empowering the next generation of microfluidic engineers. Jul 2016 In : Microfluidics and Nanofluidics. 20, 7, 103 (Journal)

- Ashour, M. & Kersaudy-Kerhoas, M. Microfluidic snap-fit assembly enabled by additive manufacturing. 2017 Advances in Manufacturing Technology XXXI. Gao, J., El Souri, M. & Keates, S. (eds.). Amsterdam: IOS Press, Vol. 6, p. 129-134 6 p. (Advances in Transcdisciplinary Engineering; vol. 6) (Journal)

Relevant Funding

Biodegradable microfluidics

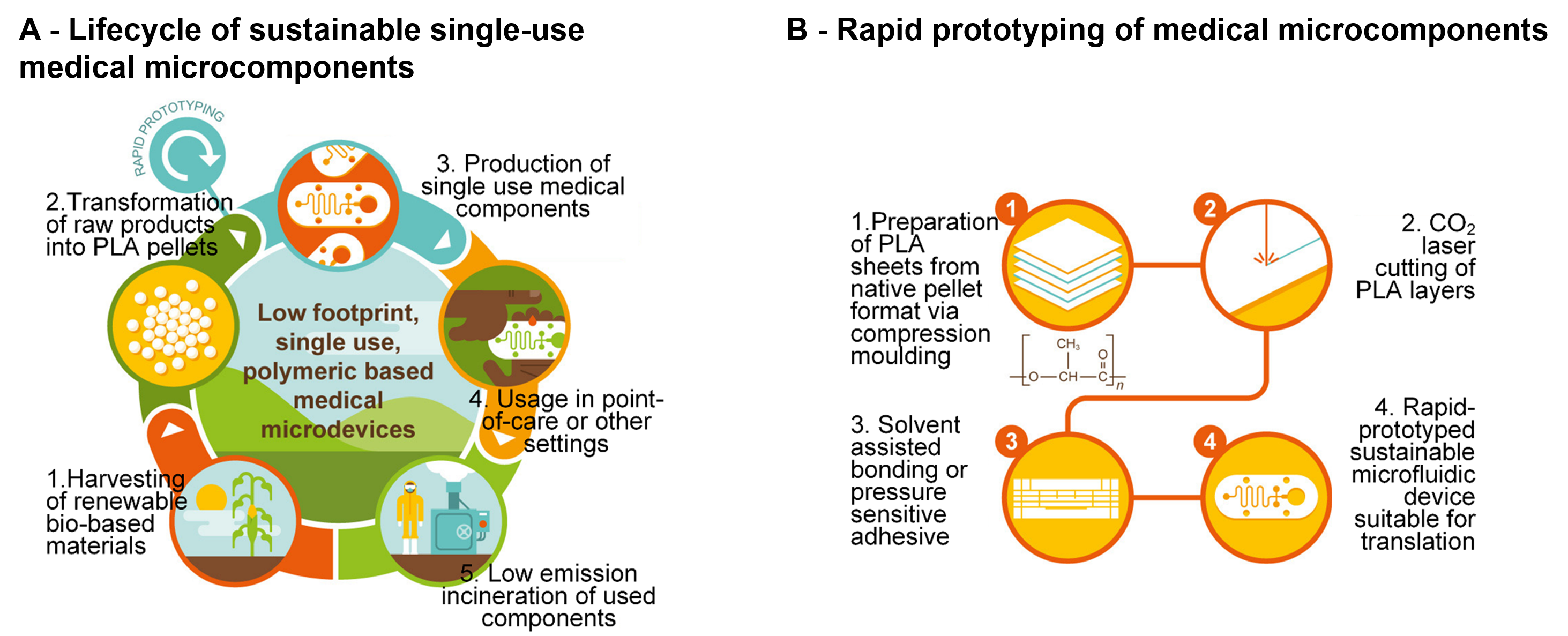

Improvements have been introduced in the production and recycling of plastic in food packaging, automotive and other large scale production industries. However, the medical sector where 20-25% of all waste is incinerated fails to keep pace with sustainability efforts. Research towards non-petroleum derived plastic disposables is still not as advanced as one might expect, especially in the microfluidic field with only a few early prototypes realised so far. Our current goal is to explore the possibility of manufacturing microfluidic chips and components using Poly-Lactic-Acid (PLA) based material. PLA is a material of choice as it is produced from renewable sources and has been demonstrated to yield a negative emission impact. PLA is compatible with a range of rapid-prototyping (fused filament fabrication, FFF) as well as high volume manufacturing processes (microinjection moulding) which makes it a candidate of choice for the development of disposable medical micro-structured components. Yet, as far as we know, the lifecycle of micro-structured disposable medical devices has not been studied which makes this study timely, especially for microfluidic cartridges. We have developed a method for the use of PLA as a substrate material in microfluidic prototype.

Relevant Publications

- Alfredo E. Ongaro, Nicola Howarth, Vincenzo La Carrubba, Maïwenn Kersaudy-Kerhoas. Rapid Prototyping for Micro-Engineering and Microfluidic Applications: Recycled PMMA, a Sustainable Substrate Material . Pages 107 -112. Series Advances in Transdisciplinary Engineering, Volume 8: Advances in Manufacturing Technology XXXII. 2018 (Journal)

- Ongaro, A. E., Keraite, I., Liga, A., Conoscenti, G., Coles, S., Schulze, H., Bachmann, T. T., Parvez, K., Casiraghi, C., Howarth, N., La Carubba, V. & Kersaudy-Kerhoas, M. Laser Ablation of Poly(lactic acid) Sheets for the Rapid Prototyping of Sustainable, Single-Use, Disposable Medical Microcomponents. 2 Apr 2018 In : ACS Sustainable Chemistry and Engineering. 6, 4, p. 4899–4908 10 p. (Journal)